Parts from retired Royal Air Force Tornado jets have been ground down and 3D-printed into new components for the UK’s next-generation military aircraft.

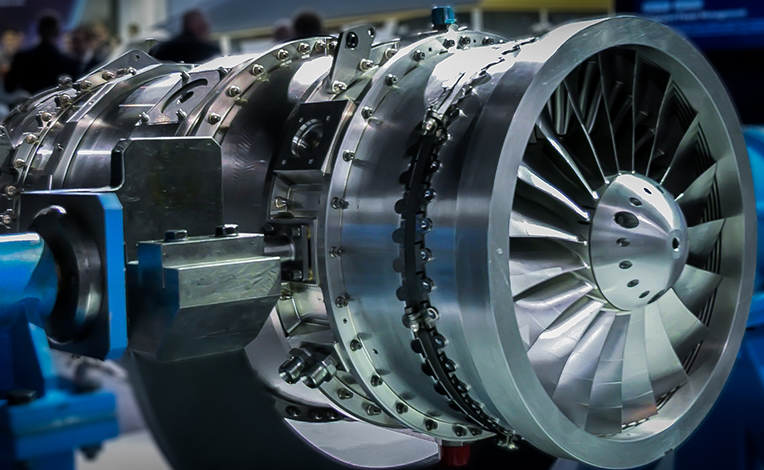

Components with high titanium content, such as jet engine compressor blades, were identified for recycling.

The parts were cleaned and processed into 3D-printed compressor blades and a nose cone by Additive Manufacturing Solutions (AMS), which were then fitted onto an Orpheus small engine concept.

Recycled Parts Successfully Tested

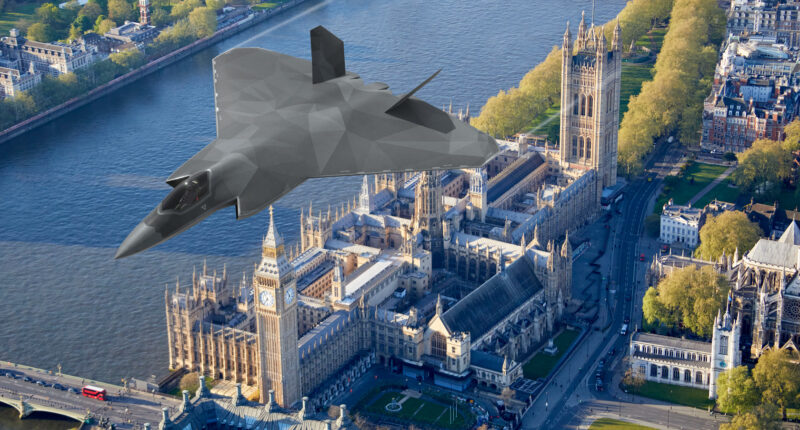

Rolls-Royce has already tested the engine for suitability and safety, with positive results validating the technique’s potential application in the future sixth-generation fighter aircraft program.

“The Tornado 2 Tempest project highlights the creativity, ingenuity and innovation defence employs in our approach to national security,” Minister for Defence Procurement and Industry Maria Eagle said.

“By working with key industry partners, we can deliver savings, reduce reliance on global supply chains and ensure our Armed Forces have the very best kit to keep our country safe.

Not only does this initiative have a positive impact on the environment and national security, it also supports the domestic defence industry acting as an engine for growth, which is at the heart of Plan for Change.”

Project Expansion

Additional surplus military assets containing high-quality steel, aluminum, and titanium are being identified for recycling under the project.

The initiative saves taxpayer money, reduces the UK’s dependence on global supply chains, and produces superior products compared to those “made through traditional forging techniques,” according to the UK Ministry of Defence.

The Defence Equipment and Support’s Defence Recycling & Disposals Team is leading the project in collaboration with the MoD FCAS team, Rolls-Royce, and Lancashire-based AMS.

“At AMS our tagline is ‘Innovative Solutions for a Sustainable Future’ and we were confident our innovations and ideas would have a great bearing on the future of a resilient supply,” AMS Director Robert Higham said.

“This project turned our proposed solutions into a reality, and we have been very humbled and grateful to the MOD and Rolls Royce, for allowing us to showcase our capability to deliver game-changing circular economy processes and parts in Defence.”