Troy Demmer didn’t set out to build a robotics company. A decade ago, he and his team at what would become Gecko Robotics started with a simple but unsettling realization: no one really knew the state of the world’s critical infrastructure.

“We fundamentally understood that the built world — our most critical infrastructure — didn’t have high fidelity data on it,” Demmer said. “That was the starting point.”

Without that data, decision-makers were flying blind. And in defense, where aging fleets and massive capital assets define readiness, that gap wasn’t just inconvenient. It was a national security issue.

In this episode of Defense Disruptors, we sit down with the Co-Founder and President of Gecko Robotics to talk about AI-powered inspections, robotic autonomy, and how Gecko is helping the US military extend the life of its most valuable (and vulnerable) assets.

Are you building game-changing tech for defense? 💪

We’re always looking to feature innovators pushing the boundaries in autonomy, AI, energy, and beyond. If your company belongs in the Defense Disruptors spotlight, get in touch with us here.

A New Way to See

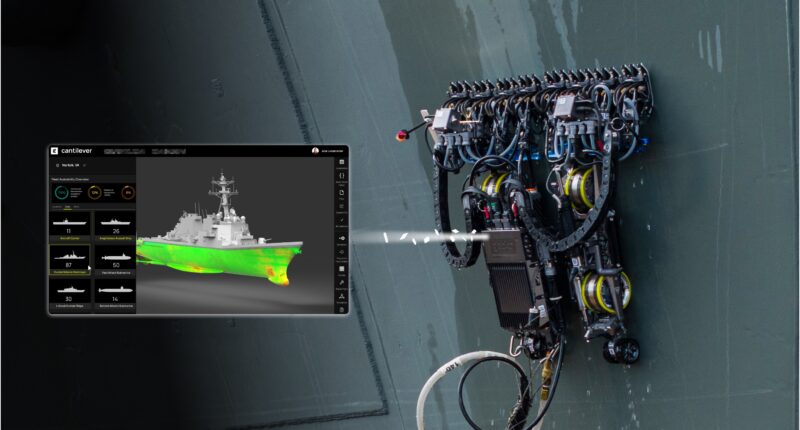

Demmer co-founded Gecko Robotics with the idea of using sensor-laden robots to capture detailed, material-level data on infrastructure. These robots, he said, can “fly, climb, walk, and crawl” on the surfaces of critical assets like ships and power plants, generating millions of data points.

“We’re a materials science-based company,” Demmer said, describing their technology as a way to “instrument these assets with sensor data” and translate that into actionable insights.

What once took days or even weeks of manual inspection — often involving humans rappelling down ship hulls — is now done faster, safer, and at a scale that simply wasn’t possible a decade ago.

Helping the Navy Stretch the Life of Its Fleet

Gecko’s profile has risen significantly in recent years, particularly with the US Navy.

The service has ramped up its work with the firm by 400 percent, a surge Demmer attributes to two urgent challenges: “We cannot build things fast enough,” he said. “And we have to extend the life of our existing assets.”

Gecko aims to close that gap. Its tech is helping create a “digital thread” through shipbuilding and maintenance, tracking everything from raw materials to the corrosion in a fuel tank.

Demmer said one recent project compared two similar ships: one using Gecko’s “personalized repair plans,” the other relying on legacy methods. The traditional repair cost $7 million, he said. The Gecko-informed repair? Just 3.5 percent of that, a quarter million.

Demmer also cited corrosion as a pervasive threat to naval readiness, calling it a “death by a thousand cuts” issue.

“Corrosion costs the world 3.4 percent of GDP,” he claimed. Gecko’s robots scan every inch of critical surfaces, detecting corrosion and deformation in areas like tanks, voids, and helicopter decks, information that Demmer said helps determine whether an aging component is still fit for duty or must be replaced.

Turning Inspections Into Intelligence

Gecko’s value proposition, Demmer described, lies in its ability to collect data at scale, data that traditional methods have struggled to capture.

The millions of data points collected by robots are then fed into Gecko’s AI-powered operating platform, Cantilever®, which creates digital twins of physical assets and surfacing key failure risks before they become catastrophic.

“AI is only as good as the data it’s trained on,” Demmer said. “Prior to Gecko, there was nothing for AI to ingest.”

That data-first mindset is now opening doors across the military. The company is working not just with the Navy but also with the Air Force on ICBM systems and aircraft inspections.

From Diagnostics to Action

Asked how Gecko stays ahead in a rapidly growing AI and robotics field, Demmer pointed to a unique focus on data quality and integration.

“Robots are still largely unemployed,” he remarked. “It’s not enough to build them, you have to make sure the data can be ingested and used.”

Now, Gecko is moving beyond inspection to autonomy.

“We’re building toward a world where robots don’t just inspect, they act,” Demmer said. That includes autonomous repairs, additive manufacturing, and subtractive manufacturing.

The long-term goal is clear: every mission-critical asset should have a digital twin, continuously updated by robots and AI. “And we need to make sure no flaw gets through the supply chain without being known and tracked,” he said.

From diagnostics to autonomy, Gecko is pushing the boundaries of what robots can do — and according to Demmer, they’re just getting started.