The US military’s effort to speed up how it builds and replaces vehicle parts is getting a high-tech lift thanks to a new $9-million research lab in Illinois.

Announced by the Grainger College of Engineering at the University of Illinois Urbana-Champaign, the facility will focus on developing advanced 3D-printing techniques, specifically for large metal components used in military ground vehicles.

The aim? To shrink production timelines, ease pressure on strained supply chains, and give the military more flexibility in how it meets shifting demands on the battlefield.

“We are building the world’s first university research center focused on large metal additive manufacturing,” said mechanical science and engineering professor Bill King, who will lead the new initiative.

“We will conduct fundamental research on material properties and part quality, and we will have a factory demonstration facility to develop new processes and technologies.”

The US Department of Defense is contributing $8.15 million to help launch the project.

A Shift in How Things Are Made

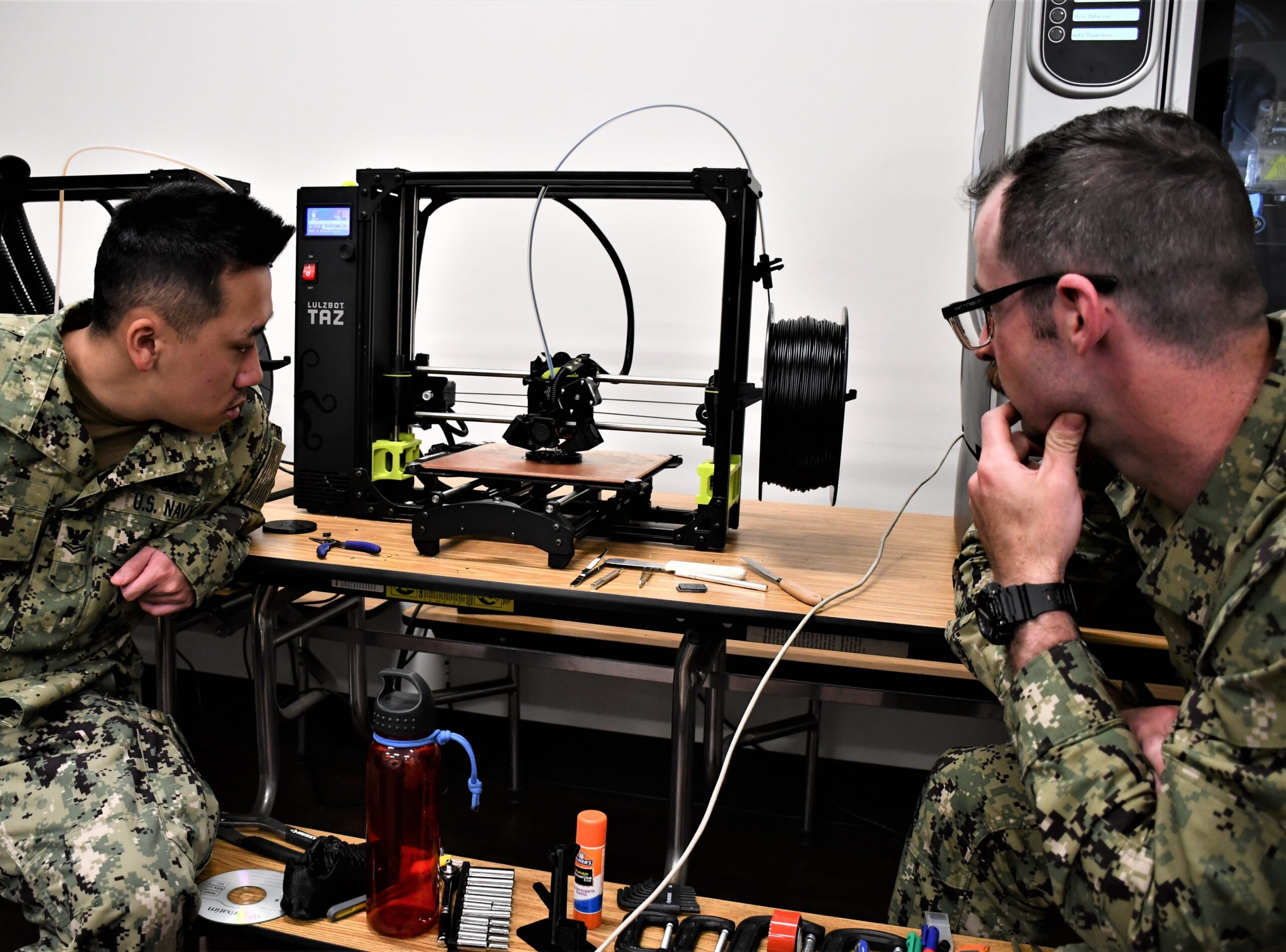

Unlike traditional manufacturing, which tends to be slow and rigid, additive manufacturing builds components layer by layer as needed. That means faster, more responsive production with less reliance on stockpiles and fewer delays.

It also allows for easier retooling, as a single machine can be reprogrammed to build whatever component is needed next.

That kind of flexibility could prove crucial for military readiness. Instead of waiting months for a replacement part, units could get what they need in days.

“We remain at the forefront of advancing Army readiness by pushing the boundaries of advanced manufacturing,” said David Gorsich, a chief scientist at the Army Combat Capabilities Development Command.

“Partnering with Grainger Engineering gives us access to world-class research that will help us answer fundamental questions about large-scale metal additive manufacturing and bring those answers to bear on real-world applications.”

Earlier this year, the army began testing additive methods to repair damaged vehicles on the battlefield, without needing to pull them out of action.

With research from the new lab, the military hopes to build on that momentum — streamlining supply chains, easing maintenance, and cutting costly downtime.