In 2019, Donatas Gendvilas was not thinking about warzones. He was thinking about wildfires. Europe had just emerged from one of its worst wildfire seasons in memory, and Gendvilas, a physicist by training, was interviewing first responders about their equipment needs.

Their response was blunt: helicopters were too expensive to operate. “It takes 3,000 to 4,000 euros per hour to fly a helicopter,” Gendvilas recalled. “We simply cannot afford that kind of cost when responding to emergencies.”

That problem became the catalyst for Airvolve, a Lithuanian startup that is now developing what Gendvilas describes as a radically simplified and lower-cost alternative to conventional helicopters — one that, in his view, could reshape how logistics and rescue operations are carried out in modern conflict zones.

Though the company initially aimed at urban air mobility, the outbreak of war in Ukraine forced a reevaluation.

“We pivoted to the defense and dual-use sector because the gap was too obvious,” Gendvilas said. “We realized the tactical airlift had essentially collapsed. We saw a need, and we went after it.”

In this episode of Defense Disruptors, we sit down with Gendvilas to talk about why helicopters have disappeared from modern battlefields, how Airvolve plans to bring them back at a fraction of the cost, and what it takes to reinvent airborne logistics in the age of drones and asymmetric warfare.

Are you building game-changing tech for defense? 💪

We’re always looking to feature innovators pushing the boundaries in autonomy, AI, energy, and beyond. If your company belongs in the Defense Disruptors spotlight, get in touch with us here.

A Crisis in the Skies

Airvolve’s founder says the numbers tell a stark story.

During the Vietnam War, more than 7,000 Bell Huey helicopters conducted roughly a million casualty evacuation missions, Gendvilas noted.

In Ukraine, despite similar levels of battlefield injuries, Gendvilas claimed that only 64 recorded medevac missions have been completed using helicopters. “That’s less than 0.01 percent of what was done in Vietnam,” he stressed. “Something has gone terribly wrong.”

The issue, he argued, comes down to two factors: cost and survivability.

Helicopter prices have risen nearly 700 percent over the past six decades, according to Gendvilas, while the battlefield has become increasingly hostile to large, slow-moving aircraft. “A 300-euro first-person view drone can take down a 20-million euro helicopter,” he said. “That’s the asymmetry we’re dealing with.”

In his view, the only way to reintroduce helicopters to modern battlefields is to make them significantly smaller and cheaper, without sacrificing critical mission capabilities.

“We’re trying to reduce the cost of airborne transportation by at least a factor of seven,” he explained. “That requires a complete rethinking of propulsion systems, vehicle architecture, and size.”

Reinventing the Rotor

At the core of Airvolve’s approach is what Gendvilas called a “reinvented propulsion system.” While he declined to share specifics, he said it draws on aerodynamic principles that are nearly a century old and are now made viable by advances in materials science.

“We didn’t reduce costs by using cheaper components,” Gendvilas stated. “We shrank the aircraft itself — dramatically — without compromising payload or range.”

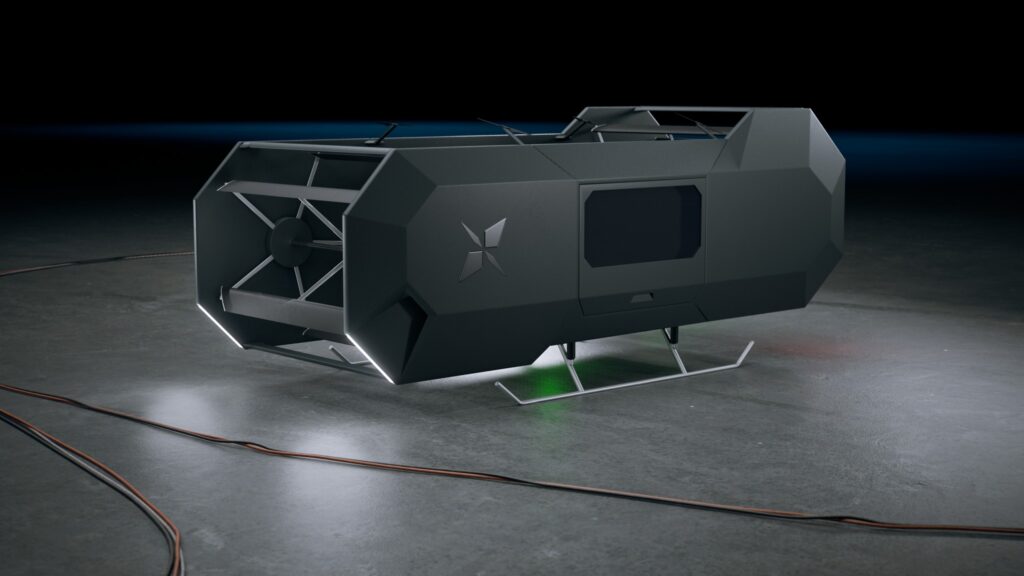

Airvolve’s prototype aircraft fits into a standard 20-foot (6-meter) shipping container, runs on conventional fuel, and can be deployed without assembly. It boasts a payload capacity of 200 kilograms (441 pounds), a range of 100 kilometers (62 miles), and over five cubic meters of internal cargo volume, a spatial efficiency Gendvilas claimed surpasses most helicopters.

“And it costs less than half a million euros to build,” he added.

The prototype is currently being assembled, with flight testing planned for the summer. Gendvilas expects an MVP (minimum viable product) ready for demonstration by the end of the year.

Built for Defense

Airvolve’s immediate focus is on military logistics and casualty evacuation, areas where traditional helicopters are either too vulnerable or too costly to deploy.

“Tactical airlift is one of the biggest gaps in the current battlefield,” Gendvilas said. “And solving it could mean saving countless lives.”

He also sees spillover potential into search-and-rescue, civil emergency response, and disaster relief — sectors that share similar payload and range requirements but have historically struggled with the economics of rotorcraft deployment.

Asked about urban mobility and commercial cargo transport, Gendvilas was cautious. He pointed to significant regulatory hurdles and certification costs that he believes are still years away from being resolved.

“Air taxis and drone logistics — they’re coming, but not yet,” he said. “We’re focused on the problems we can solve now.”

A Startup’s Struggles and Opportunities

Airvolve, by startup standards, is still small. The core team includes just eight full-time employees and a handful of specialized collaborators such as aerodynamicists, materials engineers, simulation experts, and former military planners.

According to Gendvilas, much of the team’s know-how is unique and difficult to replicate.

“We’re working in a very narrow design window where the technology works. Make it bigger or smaller and performance collapses,” he noted. “We’ve had to build everything ourselves, including rotorblades, because no one in Europe could make them to our spec.”

That lack of industrial partners has slowed progress, but Gendvilas believes it will ultimately be a strength. “We’ve become vertically integrated out of necessity,” he said. “But now, we know how to scale production in-house with fewer than 200 parts per aircraft.”

While manufacturing at scale remains a daunting challenge, Gendvilas claims their aircraft can be assembled manually at a rate of 60 units per year in a 1,000-square-meter (10,764-square-foot) facility, at a cost “10 times cheaper” than a comparable helicopter factory.

Funding, Vision, and the Road Ahead

To date, Airvolve has raised early-stage funding from Lithuanian and EU-based sources, including defense-oriented venture funds. The company is preparing to launch a Series A round later this year, with the aim of scaling production and building out supply chains.

“We’re not building a drone or another flying taxi,” Gendvilas emphasized. “We’re solving a specific, overlooked problem in defense logistics.”

Asked about expansion into other defense domains, Gendvilas was unequivocal. “We’re not chasing trends like first-person view drones or loitering munitions. Others are doing that. We’re here to rebuild a tactical airlift — and that’s a big enough problem.”

For Gendvilas, the future of battlefield mobility is not about sleek, high-tech machines. It’s about affordability, adaptability, and survivability. “If we can make airborne logistics ten times cheaper,” he said, “then we can save lives, boost morale, and maybe even change the outcome of a war.”

And that, he argues, is worth building.